Smart Microsystems Lab (Michigan State University)

Doctoral Work:

|

|

Individual Blade Control for Exploration Rotorcraft

Aeromechanical analysis is being conducted through an ANSYS FSI solver to investigate the effect of n/rev feathering on control loads. Additionally, an Individual Blade Control (IBC) test bed is being developed. IBC is a well-studied method of rotor blade pitch control that overcomes many of the limitations of traditional swashplate systems. Although IBC is well established as it relates to manned helicopters, there is little to no work studying IBC on high-speed, small-scale UAV rotor systems.

The goal of this project is to develop low-fidelity results to advise on development of a UAV IBC system on exploration rotorcraft like the Mars Helicopter. Work is conducted under general lab funds and does not currently hold dedicated funding. |

Undergraduate Work:

|

Remotely Operated Underwater Vehicle (ROV)

The ROV was designed for the SML to act serve as a test bed for both onboard autonomous underwater control and exterior mounted research projects. The ROV is wirelessly controlled via a Bluetooth PS4 DUALSHOCK 4 controller. The ROV is designed in such a way that onboard controllers, sensors, and wireless communication hardware can be swapped out and interfaced between different systems. The ROV also contains an aluminum frame on the bottom for mounting of exterior research projects.

|

|

Autonomous Electric Motorboat

The motorboat was designed to act as a test bed for autonomous control and externally mounted research projects. Primarily, the motorboat is designed to work with a custom built sonar system for mapping underwater surfaces. The motorboat currently uses Pixhawk hardware, but is interfaceable with any system controller. The boat is capable of streaming live underwater video from the sonar system. Currently, the boat can be controlled via a handheld controller or a preprogrammed path within the limits of the ArduPilot mission control software.

|

|

Autonomous Sailboat

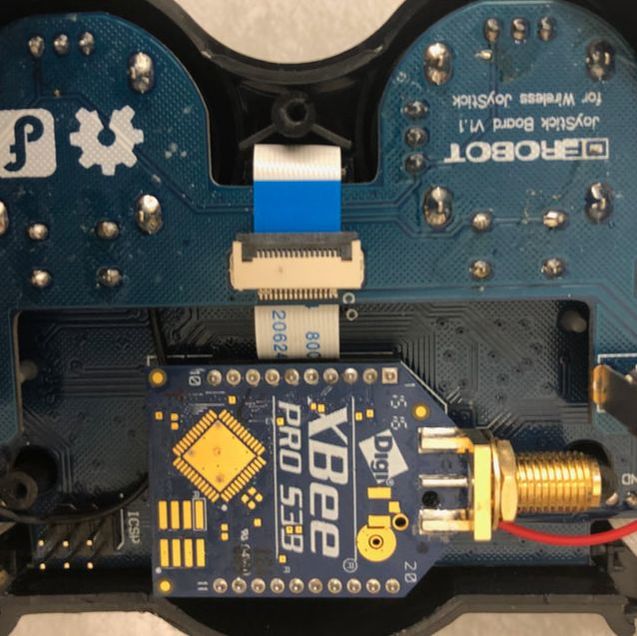

The ongoing autonomous sailboat project has the goal of creating a fully autonomous sailboat with the capability of generating its own power at a rate great enough to permanently sustain itself under constant operation. In its present state, the project contains a completed remote control electrical system and a mechanical system capable of operating under extremely low power requirements. The project currently relies on Arduino architecture and communicates using XBee Pro S3Bs, which have a theoretical range of 28 miles given an appropriate Fresnel zone and high gain antennas. The project is currently focused on the construction of a hull, the addition of solar panels, and the implementation of an autonomous control algorithm.

|

|

Soft Robotic Glove

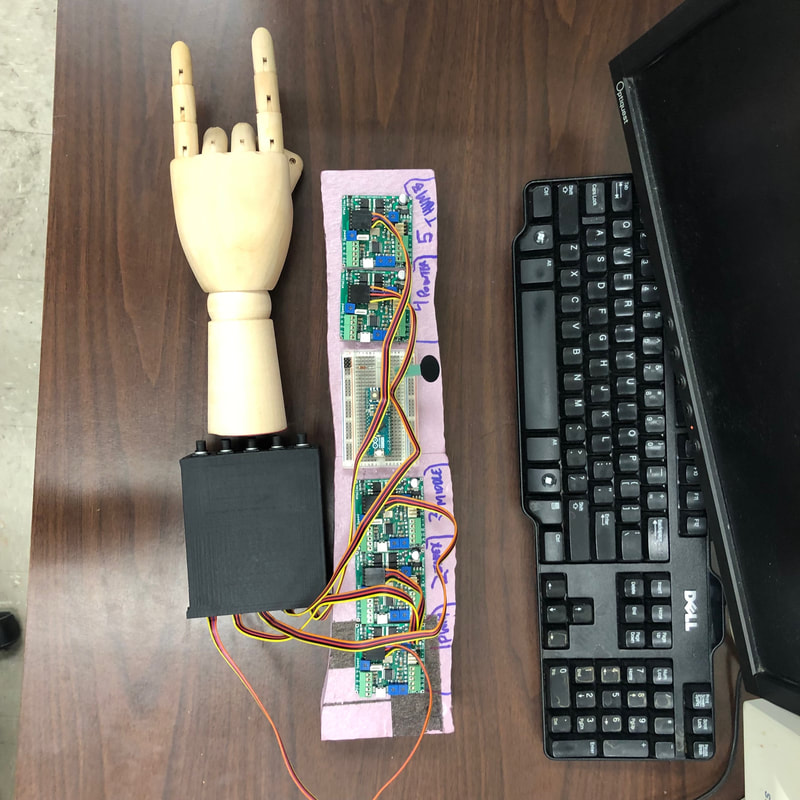

The soft robotic glove project is an extension of the lab's long time focus on soft robotics. This project was designed to explore and develop the application of soft robotics and sensors to wearable devices, similar to the gloves developed by Harvard and NASA/General Motors. The picture to the left shows the prototype forearm assembly, which houses tendon actuators and various electronics.

|

Student Design Teams

|

MSU Rocketry Team

The MSU Rocketry Team was founded in the 2016-17 season. That year, we attained 12th place overall at the Spaceport America Cup. We competed in the 10,000 ft class, reaching only 34 feet over our target. My primary responsibility was the design of the fins.

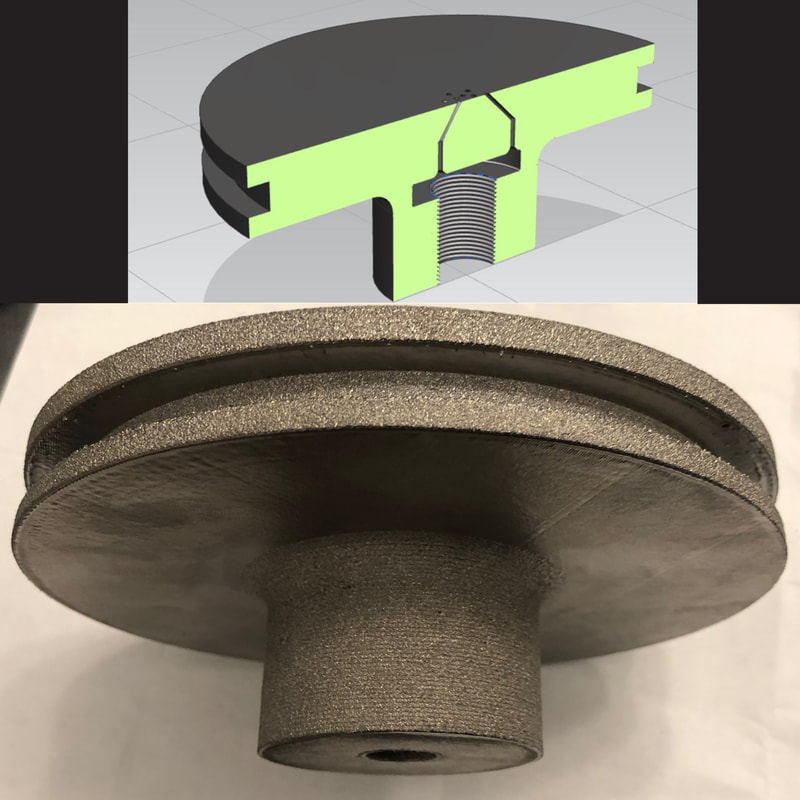

In 2018-19, we developed a hybrid motor. My focus was on the design and manufacturing of the oxidizer injector plate. The injector plate was was 3D printed out of titanium and finished on a mill and lathe. Due to costs, it was designed primarily by literature review. It features 14 small injector orifices with impingement angles ranging from 90 to 60 degrees. |

|

Farmington FIRST Robotics Team #3414

My high school's FIRST Robotics Competition Team was my first true exposure to engineering design and build. Our team developed a robot capable of picking up and accurately shooting frisbees at over 40 mph, then doing a pull-up to score extra points in the live action game. The robot was also capable of blocking frisbees thrown by opponents. This robot took our team to the world championship in our team's first year of existence.

|

Personal Work

|

Sound Responsive Color Chasing LED Array

This LED array was an Arduino based system that synchronized to music and changed color chasing modes to a beat. The Arduino took an audio digital input from a computer, converted the signal to analog, split the frequency into seven frequency bands on both the left and right stereo signals, and used a shifted 5-point running average function to determine the beat of the audio source. The Arduino then controlled a color chasing LED controller which in turn controlled the LED array. This project required a significant amount of experimentation and research. First, significant analysis was needed to create an optimal control algorithm that worked across a large variety of music. This required developing a Python program to plot hundreds of songs’ audio signals with differing averaging functions to find the ideal function to properly trigger the LEDs. Second, significant experimentation was needed to interface the Arduino with the LED controller, which required precise electrical command inputs to bypass it’s built-in control interface.

|

|

Engineering Workstation

This workstation was hypothesized after my laptop was unable to handle many of the CAD, CFD, and FEA problems I was using it for in engineering projects. The goal was to design a workstation capable of strong computing that also served as a high quality home entertainment PC. The workstation operates on a liquid cooled 16 Core Intel Xeon CPU with 32GB of RAM. These parameters were chosen based off of the recommended value proposition of common CFD and FEA softwares and technical qualities of the hardware, such as the Intel Xeon's ability to handle high precision floating point numbers. The system was designed to handle mid-sized projects at high speed, as opposed to large projects at lower speed. In regards to the home entertainment features, the workstation was outfitted with an array of high quality equipment, such as a sound card, Blue-ray player, and high speed WiFi receiver in case of ethernet failure, a feature that has proved life-saving many times.

|